Product ID: UCMIG20L2006

Report ID:

UCMIG20L2006 |

Region:

Global |

Published Date: Upcoming |

Pages:

165

| Tables: 55 | Figures: 60

The rising adoption of FRP vessels in chemical plants owing to their beneficial properties such as lightweight, easy to handle, can be customized easily depending upon customer requirement, and simple installation process is the factors anticipating the FRP vessels’ market growth. In addition, the key market trend in the global market is the growing need for municipal wastewater treatment and the rising number of portable water treatment plants. On the contrary, to performance degradation under the influence of UV rays, FRP has low elastic modulus, thus, vessels made up of FRP lack rigidity, have poor long-term temperature resistance, and these vessels are susceptible. In the coming years, the factors expected to boost the FRP vessels market are the government’s inclination towards the adoption of clean fuel and improving the market of natural and fuel cell electric vehicles. The demand for FRP vessels is fuelled up due to the growing application range of FRP vessels in different sectors such as in medical for gas contamination and in tanks used in scuba.

This report is being written to illustrate the market opportunity by region and by segments, indicating opportunity areas for the vendors to tap upon. To estimate the opportunity, it was very important to understand the current market scenario and the way it will grow in future.

Production and consumption patterns are being carefully compared to forecast the market. Other factors considered to forecast the market are the growth of the adjacent market, revenue growth of the key market vendors, scenario-based analysis, and market segment growth.

The market size was determined by estimating the market through a top-down and bottom-up approach, which was further validated with industry interviews. Considering the nature of the market we derived the Environmental & Facilities Services by segment aggregation, the contribution of the Environmental & Facilities Services in Commercial & Professional Services and vendor share.

To determine the growth of the market factors such as drivers, trends, restraints, and opportunities were identified, and the impact of these factors was analyzed to determine the market growth. To understand the market growth in detail, we have analyzed the year-on-year growth of the market. Also, historic growth rates were compared to determine growth patterns.

Our industry expert will work with you to provide you with customized data in a short amount of time.

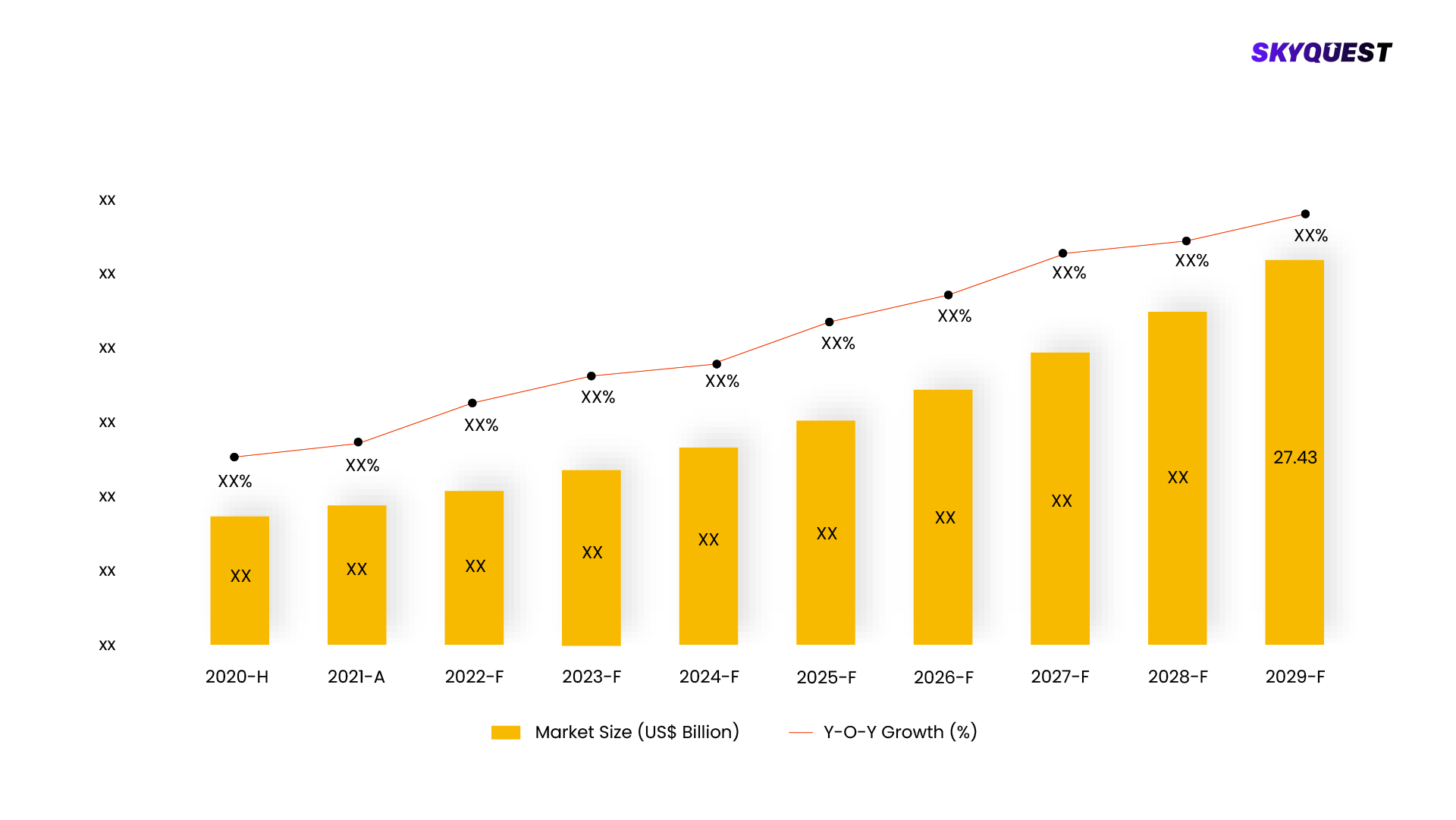

REQUEST FREE CUSTOMIZATIONThe global market for FRP Vessels was estimated to be valued at US$ XX Mn in 2021.

The global FRP Vessels Market is estimated to grow at a CAGR of XX% by 2028.

The global FRP Vessels Market is segmented on the basis of Fiber Type, Resin, Application, Region.

Based on region, the global FRP Vessels Market is segmented into North America, Europe, Asia Pacific, Middle East & Africa and Latin America.

The key players operating in the global FRP Vessels Market are Sainath Industrial Corporation (SIC), Plas-Tank Industries Inc., Augusta Fiberglass, Group Surya, JRMS Engineering Works, TROY Dualam Inc., Kaymo Fiber Reinforced Plastic Manufacture Co. Ltd., Swami Plastic Industries, Palmer, Link Engineers.

Want to customize this report? This report can be personalized according to your needs. Our analysts and industry experts will work directly with you to understand your requirements and provide you with customized data in a short amount of time. We offer $1000 worth of FREE customization at the time of purchase.

Product ID: UCMIG20L2006